What is Barcode Inventory Management ?

Barcode inventory management is a tracking system that uses barcodes to scan and keep count of products in an inventory. Barcodes are machine-readable representation of a product's details, like its brand name, manufacturer, dimensions, weight, expiration date, and so on. Barcodes are scanned by barcode scanners and their data captured by an inventory management system.

The Ultimate Primer on Barcode Inventory Management For Every Kind Bar

What is Barcode Inventory Management?

Barcode inventory management is a system of inventory tracking that uses barcodes to keep count of the inflow and outflow of inventory. Barcoding inventory gives an exact tally of inventory levels and helps a business owner get a better grip on order management . This inventory system is quicker, and more accurate and efficient than the manual method of inventory control done with spreadsheets.

Manufacturers use the barcode system to assign a unique product code to every item they produce. These are then printed on labels and pasted on a product. They are scanned with the help of a barcode scanner and the product details are automatically transferred to the inventory management software.

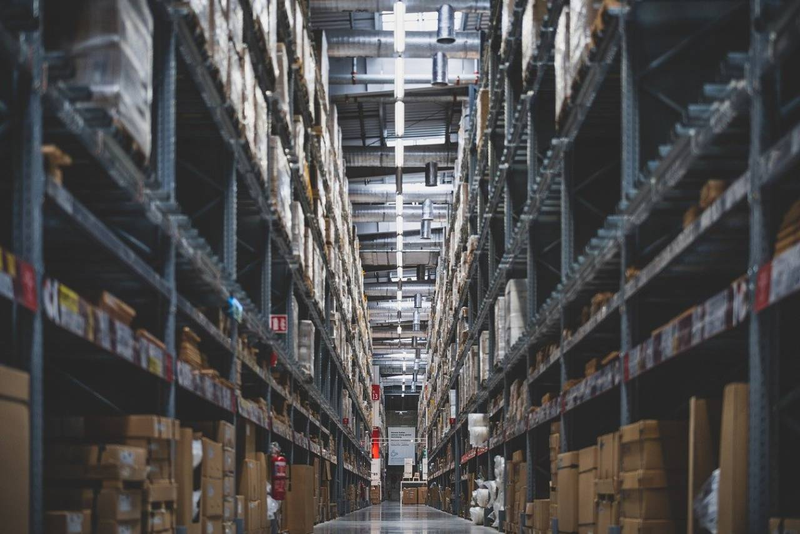

Barcodes are used in asset tracking across the board, from a small business to a big enterpriseeveryone's using them for inventory control and order management today. But, its was the Fast Moving Consumer Goods Sector that was first to use barcodes . The first product to have its barcode or product code scanned was Wrigley's Chewing Gum in 1974. Apart from grocery stores and supermarkets, the barcode inventory system soon became integral to warehouse management . But it has since found its way into almost every part of retail and service.

Mobile AppInventory AppsBar Inventory

- Date of manufacturing

- Date of expiry

- Country of origin

- Manufacturer details

- Cost

Key Components of a Barcode Inventory Management System- Hardware

A barcode inventory management system is a compact suite of hardware and software. We lay it out for you here-

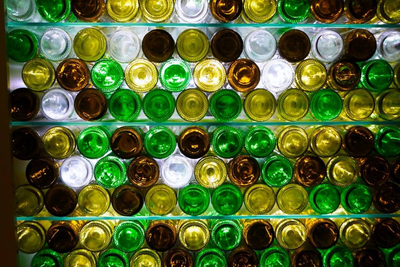

Barcode Inventory Hardware

The hardware essentials of a barcode inventory system are a barcode scanner and a smartphone or computer. Blue-tooth or Wifi liquor scales are an added asset for inventory management in a bar. Bar inventory needs more than product count; liquor levels need to be noted too. That's where electronic scales help. Weighing liquor bottles on Bluetooth or Wifi-enabled scales add product quantity to the stock count, providing complete inventory control.

- Barcode scanner

A barcode scanner is essential to read a barcode. The two most popular types of barcodes are one dimensional (parallel lines and spaces) and two dimensional (of which QR codes are a part). There are several types of scanners around. These include pen wands, CCD (charge coupled device) scanners, and laser scanners. Barcode readers best suited to bar stocktake are lightweight, portable, handheld devices. While a small business with limited inventory can use the camera on a smartphone or tablet to scan QR codes and barcodes, businesses with larger stock may want to use dedicated handheld scanners for quick and accurate reading.

- Barcode generator

While most liquor bottles and supplies come with their own barcodes, a bar may want to include items in inventory that don't have a barcode. They can use a barcode generator to create and print their own barcode stickers. Several companies offer free barcode generator software online. These can be printed on any ordinary printer.

- Smartphone or laptop

Smartphones and computers are the ledgers of modern inventory. Where manual systems had a stock-taker noting liquor stocks in books, inventory apps today categorize and store liquor data automatically on smartphones, tablets, desktop computers, or laptops. If the app is cloud-based, the data can be accessed from any device by multiple users.

Bar ManagementBar InventoryBest Free

There are several ways to take inventory, but not all of them are quick and easy.

Barcode inventory management makes stock-taking a breeze. That’s why you need to check it out today.

Key Components of a Barcode Inventory Management System- Software

Barcode inventory management software deciphers information stored in barcodes and organizes it for easy reading. A product's details are categorized neatly by alcohol type, brand, manufacturer, supplier, par level, or by any other parameter the bar manager sets. No matter how large the inventory, stock levels for any item can be found in seconds with the software's search function.

Modern inventory management systems integrate barcode software with a bar's POS software. Together, they can then do much more with inventory data. They can crunch that data to produce up-to-the-minute reports on daily, weekly, or monthly consumption, identify patterns in seasonal demand, spot variance cost, calculate pour cost, and automate ordering. The software's intuitive analytics spots leaks in inventory management and offers useful advice on how they can be plugged for increased profits.

How Does Barcode Inventory Management Work?

Managing and updating inventory can be time-consuming and laborious. And when it's a chore, it becomes susceptible to error and miscalculation. Errors in stocktake lead to poor order management that can send a business reeling. It's why inventory control and asset tracking are the cornerstones of a business. Barcoding inventory strengthens that foundation.

The barcode system of inventory management is quick and efficient and can capture data in seconds. A bartender has to simply use a handheld barcode scanner or smartphone camera to scan barcodes on bottles. Coupled with Bluetooth or Wifi weighing scales, liquor levels are also updated. The inventory software or app captures the product's details and stock levels and files it in its database, cataloguing it for easy review.

The inventory software quickly tallies bottle count and par levels, to indicate which brands need to be restocked and which are building up as deadstock. Superior inventory management systems can be calibrated to automatically reorder stocks from suppliers when they hit par level. They can also produce weekly, fortnightly or monthly reviews of sale trends and forecast demand.

Barcode inventory software is often cloud-based and inventory apps can be downloaded on multiple devices. Stock-take can then be done by multiple users, simultaneously or across multiple locations. Inventory data is centralized and accessible for review anytime, anywhere.

Credit CardDay DayDemand PlanningCustomer Stories

Is Barcode Inventory Management the Best Method of Inventory?

Manual inventory is slow tedious work, with a high risk of error. It involves a bar's staff spending time and effort eyeballing each and every product in a bar and painstakingly noting down its details on a spreadsheet. With bar inventories growing (and staff shrinking), this method of inventory has its days numbered.

Barcode inventory management on the other hand ticks all the right boxes. Let's count them . . .

- Barcode scanners improve efficiency and gather data quickly and accurately.

- The easy use system requires little to no training time, which means time and money saved acquainting new staff with the inventory system .

- Barcode systems are versatile, allowing smartphones to double as barcode scanners .

- Inventory software can track stock-take by employee. This makes it possible to assess achieved targets and spot errors.

- All data is centralized and can be reviewed by bar managers or owners any time, even on a mobile app.

- The data analysis is accurate as inventory items are tracked in real time.

- Alerts and notifications pop up if errors occur during stock-take or when the inventory hits a preset threshold.

- Reports generated can help a small business improve order management .

- Integrated with a POS system inventory data can be tallied with receipts and purchase order figures to gain an overview of the bar's operations.

Take stock of inventory is an essential part of bar management, but it can be slow and error-prone.

Thankfully, barcode inventory management makes the job quick and easy. Know more about it here.

How Can Barcode Inventory Management Boost Business?

Over the last decade, more and more sectors have been using barcodes for tracking inventory from retail, to foodservice, hospitality and healthcare. It's not hard to see why businesses are turning to this asset tracking tool en masse. It benefits business in more ways than one.

- Barcoding inventory is quick and easy, allowing more than twice the number of items than can be inventoried on a spreadsheet. This frees up staff to focus on other revenue-generating tasks at the bar.

- By minimizing human error it brings a level of accuracy and precision to stock-take. This prevents double entries, data fudging, and missed entries that can arise from manual inventory. Every purchase order will now reflect the reality of your stockroom. It will prevent you from over-ordering or running short of a product. A well-stocked bar is a much-frequented bar.

- Cloud-based barcode systems centralize inventory data, making it easier to review and manage stocks across multiple locations. A large business can be better handled this way.

- By tracking stock-take by individual staff members, this system brings greater transparency, which translates into greater accountability.

- Today, QR codes and barcodes are rigged with GPS features that allow real-time asset tracking .This leads to greater surveillance of your products and reduces the risk of theft and misplacement.

- Inventory reports generated by modern inventory management systems chart demand trends that help a bar optimize best-selling products and leverage slow-movers through smart menu planning.

How Much Does a Good Barcode Inventory Management System Cost?

The cost of a barcode inventory management management system depends on whether you want the full suite of hardware and software, or just the software. Several companies promote the use of smartphones as barcode scanners . These work with mobile inventory apps to scan different types of barcodes. But for those interested in the whole deal, the basic cost of a full-fledged barcode system begins at $1000. This includes a printer to make customized barcode labels, a handheld barcode scanner and the inventory software .

If, however, you only want barcode inventory software, several companies offer different subscription packages to their inventory programs. These begin as low as $50 a month, with features multiplying with the cost. Basic packages limit the numbers of devices on which the inventory app can be downloaded. Some limit the number of items that can be inventoried. Some cut back on features like forecasts and reports.

When investing in a barcode inventory system, it's important to not only plan for the present size and operations of your bar, but project for future growth as well. A modern inventory management system is a always a good investment that is sure to grow your business.

Top 4 Barcode Inventory Management Systems for 2022

The market is crowded with barcode inventory management systems, and it's hard to make a choice. This is why we've done the spadework and have rounded up the best for you.

- ZipInventory- The best barcode inventory software around, it guarantees quicker shelf-to-sheet inventory counts. Its ability to track waste and variance will help you plugs the leaks and reduce losses. The superior analytics of this software streamlines your data and summaries it in easy-to-read, actionable reports.

- Asset Panda- Asset Panda is a powerful cloud based inventory tracking platform. Its asset tracking feature consolidates all asset information, including histories, in one place, making it easy to find. The software can be used by multiple users, with different levels of access and control granted to each.

- Fishbowl- It is an inventory solution for all sizes of business. With Fishbowl, you can customize and print your own barcode labels. You can also move inventory easily from one location to another. This is great for bars with multiple locations.

- inFlow Inventory- This barcode software offers both hardware and software inventory solutions. Should you choose not to invest in their nifty barcode printer and scanner, you can still use the app on your smartphone, turning it into a barcode scanning tool. Their help center offers full customer support via live chat, email and phone.

A good bar relies on good inventory. And good inventory relies on a foolproof stock-taking system.

You can’t go wrong with barcode inventory management. It’s the only way to keep count today.